quality control that protects your brand

100% visual inspection, dimensional checks, and batch traceability—so you get consistent quality without last-minute surprises.

- 100% appearance check

- Random testing for key functions

- Clear updates at every stage

What Usually Goes Wrong in Bulk Orders

Most after-sales issues come from small inconsistencies that weren’t caught early.

①

Surface scratches & mixed packing

Plated pieces get micro-scratches when mixed together or packed without separators.

②

Color / plating inconsistency

A slight tone shift across batches becomes obvious under store lighting and in photos.

③

Weak parts that fail in use

Clasps, jump rings, and chains can pass “looks good” but fail in real wear.

Our QC System, at a Glance

Every order follows the same checklist. If anything deviates from the approved sample, we stop and confirm with you before moving forward.

100% Visual Inspection—Piece by Piece

We inspect every piece against the approved sample for surface finish, plating coverage, color consistency, and craftsmanship details.

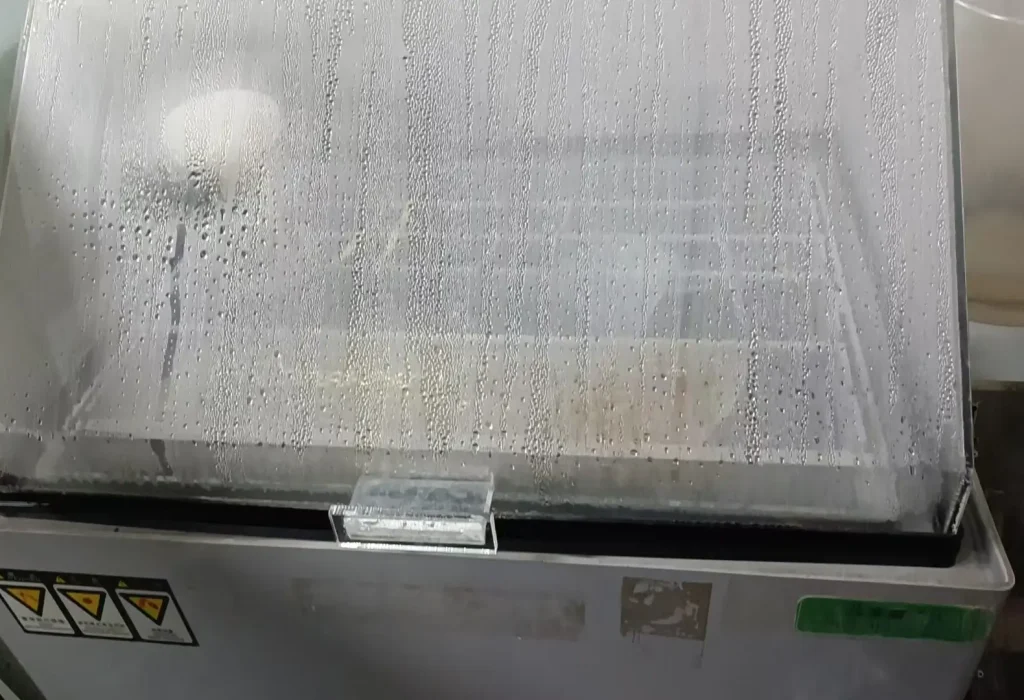

Separated Packing to Prevent Scratches

Plated jewelry can scratch easily when mixed. That’s why we pack pieces separately and use protective layers to keep finishes clean during shipping.

Dimensional Checks for Fit & Consistency

Critical dimensions are checked to ensure components match, parts fit properly, and repeat orders stay consistent.

Batch Traceability & Transparent Updates

If there’s an issue, the key is not hiding it—it’s catching it early and keeping you informed.

Dedicated follow-up for each production stage

A responsible person tracks progress and exceptions.

Clear checkpoints with photo updates

You get updates when sampling, bulk starts, QC begins, and packing completes.

No last-minute surprises

If something changes, we communicate immediately and propose options.

Functional Testing Based on Product Type

We run practical tests on key parts to reduce returns and complaints.

Strength & Structure

Plating & Surface

How

We Handle Issues.

- Stop & isolate the batch

- Report with photos + root cause

- Fix plan + timeline confirmation

We aim to solve issues inside production—not after delivery.

Want a QC Checklist for Your Next Order?

Tell us your product type and target market. We’ll share a QC checklist and packaging suggestions to reduce after-sales risk.